During Burner Week, we’re taking a closer look at the products that are critical to flame safeguard and combustion control.

Below, proven components are in the spotlight, each playing a distinct role in maintaining safety, stability, and efficiency, whether that means sequencing ignition, maintaining gas pressure, or ensuring clean flow control. Together, they form the foundation of reliable burner management used in commercial and industrial burner systems.

For a more detailed look at combustion products, explore the Burner Book, a quick-guide catalog covering flame safeguard controls, gas regulators, valves, and accessories that keep burner systems operating at their best.

Honeywell RM7890A1015 – Microprocessor-Based Flame Safeguard Control

The Honeywell RM7890A1015 is a microprocessor-based primary control designed to supervise automatically fired gas, oil, or combination-fuel burners. It provides complete burner sequencing, from purge and pilot ignition to main flame operation and safe shutdown. By integrating safety checks, status indication, and diagnostic memory, the RM7890A1015 delivers a dependable and service-friendly safeguard solution.

The controller operates on a 120 VAC, 50/60 Hz power supply and features an intuitive plug-in subbase design for fast installation and replacement. The RM7890A1015 continuously performs system self-checks during every operating cycle, verifying flame presence, amplifier integrity, and limit circuit reliability before enabling fuel.

Technical Capabilities:

- Controls purge, ignition, pilot, and main fuel stages with precise timing and safety interlocks

- Operates with compatible Honeywell 7800 Series amplifiers and subbases

- LED status lights for Power, Pilot, Main, Flame, and Alarm provide clear visual feedback

- Non-volatile memory retains fault history and lockout information after power loss

- Optional display modules offer expanded status readouts and system data

- Built-in fault diagnostics reduce troubleshooting time and improve service reliability

- Supports ControlBus™ communication for remote monitoring and integration with building systems

- Vibration rated to 0.5 g for use in demanding environments

The RM7890A1015 is used in both new and retrofit burner systems across commercial and industrial applications. Its self-diagnostic logic and repeatable sequencing make it a trusted standard in flame safeguard protection.

Why it matters:

The RM7890A1015 provides consistent, verifiable flame supervision and simplifies maintenance through its modular design. It gives technicians clear visibility into system status and history, ensuring reliable protection across every start-up and shutdown cycle.

Fireye MEC120 – Modular Flame Safeguard for Flexible Burner Management

Compact, configurable, and designed for versatility, the Fireye MEC120 is part of the MicroM Series of flame safeguard controls. It provides complete burner sequencing and safety supervision in both gas and oil-fired applications. Using a microprocessor-based platform, the MEC120 manages purge, ignition, and main flame operations with field-adjustable timing and lockout settings.

This control operates on a 120 VAC, 50/60 Hz power supply with typical power consumption of approximately 12 VA. It is rated for ambient temperatures from –40 °F to +140 °F, allowing for use in both indoor and outdoor control panels.

The MEC120 features a modular architecture, making it compatible with Fireye configuration and display modules for custom setup and detailed diagnostics.

Technical Capabilities:

- Manages burner startup, flame supervision, and safety shutdown with microprocessor logic

- Accepts plug-in configuration modules for purge timing, trial-for-ignition, and flame failure response

- Compatible with both ultraviolet (UV) and flame rectification scanners

- Provides dry-contact relay outputs for fuel valves, blower motors, and alarm circuits

- Optional ED510 display module shows system status, flame signal strength, and fault codes

- Supports communication interfaces for data access and system integration

- Meets UL and NFPA requirements for flame safeguard operation

- Constructed for retrofit compatibility with legacy Fireye M-Series systems

The MEC120’s modular design means components can be added or replaced without disturbing wiring or mounting, reducing downtime during service. Its advanced self-checking circuitry provides consistent performance and reliable safety control under varying load conditions.

Why it matters:

The MEC120 delivers precise sequencing, reliable flame monitoring, and modular flexibility that allows systems to evolve without full controller replacement. It is a durable safeguard solution suited to both new and retrofit combustion systems.

Maxitrol 325-L Series – Precision Gas Pressure Regulation for 2 psi Systems

Stable gas pressure is essential for consistent burner operation, and the Maxitrol 325-L Series is designed to provide that stability. These lever-acting regulators maintain steady outlet pressure in 2 psi piping systems for residential, commercial, and light industrial gas service. Built for precision and reliability, the 325-L Series ensures smooth burner performance even when inlet conditions or flow demands fluctuate.

The 325-L Series regulators use a lever-acting design with positive dead-end lockup, which allows for accurate pressure regulation at low flow rates, including pilot conditions. Their aluminum bodies provide a balance of strength and corrosion resistance while keeping installation weight manageable.

Available in multiple sizes, the series covers applications ranging from small appliances to multi-load burner systems.

Technical Capabilities:

- Inlet pressure: up to 2 psi (13.8 kPa), with optional models supporting 5 psi using an overpressure device (OPD)

- Outlet pressure range: 3.5" to 12" w.c., depending on spring selection

- Available sizes: 3/8" to 3" NPT for capacities from pilot flow to full appliance load

- Lever-acting design for fast response and stable control under varying demand

- Positive lockup mechanism prevents gas creep when downstream demand stops

- Operating temperature: –40 °F to +205 °F (–40 °C to +96 °C)

- Constructed from lightweight, corrosion-resistant aluminum

- Certified to CSA and ANSI performance standards

The 325-L Series regulator can be mounted in multiple orientations for ease of installation. Its balanced design minimizes outlet pressure variation, which helps maintain efficient combustion and steady flame characteristics.

Why it matters:

The Maxitrol 325-L Series ensures consistent downstream gas pressure for safer ignition, stable flames, and optimized combustion efficiency, regardless of load changes or upstream pressure shifts.

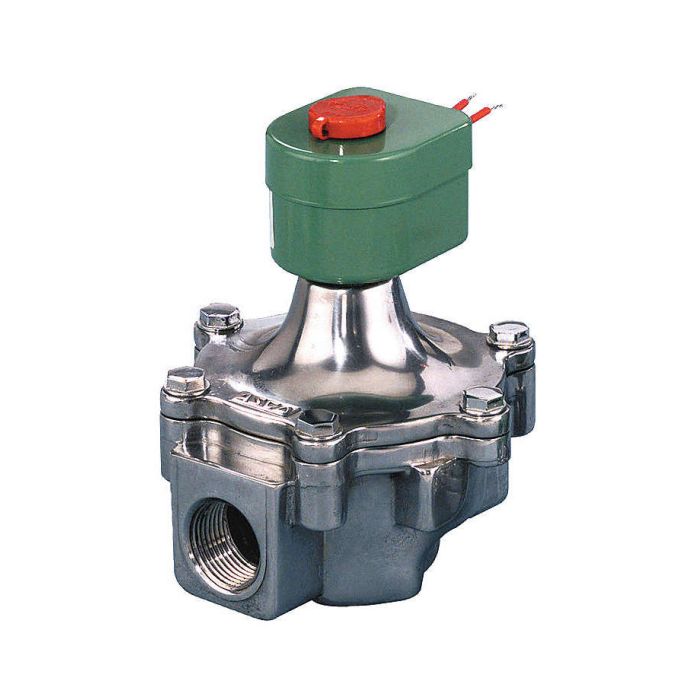

ASCO 8215C053 – High-Flow Solenoid Valve for Air and Gas Control

Precise valve performance is critical in combustion systems where air and gas flow must be controlled quickly and safely. The ASCO 8215C053 is a two-way solenoid valve engineered for high-flow capacity and dependable shutoff in both air and fuel-gas applications. Its lightweight aluminum body offers durability without excessive mass, and its compact form factor allows for easy integration into burner assemblies.

This valve is part of the ASCO 8215 Series, known for reliable operation across a wide temperature range and adaptability to multiple voltages. The 8215C053 model is typically configured as a normally open valve, designed to close securely when energized, making it suitable for both safety and flow control applications.

Technical Capabilities:

- Valve size: 1" NPT with flow coefficient (Cv) of approximately 18–22

- Pressure rating: up to 5 psi for air or inert gas; compatible with fuel gas under certified installation

- Operating ambient temperature: –40 °F to +150 °F (–40 °C to +66 °C)

- Coil voltage options: 120 VAC, 60 Hz standard (110 VAC, 50 Hz optional)

- Aluminum body construction for corrosion resistance and reduced weight

- High-flow capacity supporting over 1,000,000 BTU/hr in gas service

- UL-listed and CSA-approved for fuel gas applications

- Quick-acting solenoid mechanism for responsive opening and closing cycles

The ASCO 8215C053’s design minimizes pressure drop across the valve and ensures reliable sealing for precise control of air or fuel delivery. It is widely used in burner trains, safety interlocks, and high-capacity combustion systems where accuracy and response time are critical.

Why it matters:

With its high flow capacity, broad operating range, and proven reliability, the ASCO 8215C053 provides consistent, responsive performance for combustion systems that demand both speed and safety.

Testo 0564-3004-93 – Commercial Combustion Analyzer Kit

Combustion systems rely on more than dependable components; they depend on accurate information. The Testo 0564-3004-93 Commercial Combustion Analyzer Kit gives service professionals the data they need to confirm efficiency, safety, and compliance across every burner and boiler they maintain.

Built on the advanced Testo 300 platform, this analyzer captures real-time readings of oxygen (O₂), carbon monoxide (CO), temperature, and draft to provide a complete picture of burner performance.

Each reading is displayed on a responsive Smart-Touch interface designed for clarity in the field. Technicians can store data directly on the instrument or export it wirelessly using the Testo Smart App for fast documentation and reporting.

Every detail of the kit is engineered for precision and durability, from automatic sensor protection that prolongs sensor life to a robust magnetic housing that allows hands-free testing during service. Its rechargeable lithium-ion battery supports extended use, while integrated zeroing and CO dilution simplify setup between measurements.

Technical Capabilities:

- Measures O₂, CO (up to 4,000 ppm), temperature, draft, and differential pressure

- Automatic CO dilution for safe measurement of high concentrations

- Automatic zeroing of gas and draft without removing the probe

- Smart-Touch HD display with glove-friendly, intuitive navigation

- Integrated memory for digital reporting and on-site data sharing

- Rechargeable lithium-ion battery with up to 10 hours of continuous operation

- Durable housing with magnetic back for hands-free testing

- Wireless connectivity through the Testo Smart App for instant documentation and data transfer

- Supplied with sensors, probes, chargers, and a hard-shell carrying case for portability and protection

The Testo 0564-3004-93 combines measurement precision with field-ready durability. By streamlining testing and reporting, it helps technicians verify optimal combustion, ensure safety compliance, and maintain system efficiency with confidence.

Why it matters:

Accurate readings and simple operation make the Testo 0564-3004-93 an essential diagnostic tool for any technician working to improve combustion safety and efficiency.

CSD-1 Certification Training

Understanding combustion safety standards is just as important as selecting the right equipment. The CSD-1 Certification Training from Cochrane Tech Services helps technicians, contractors, and facility personnel stay compliant with Michigan’s boiler safety requirements while deepening their knowledge of commercial burner operation.

This one-day course provides a focused review of the ASME CSD-1 standard and teaches attendees how to properly test, document, and certify boiler controls in accordance with state regulations. Led by NATE-certified instructor Phil Forner of MIACCA, the session combines classroom instruction with real-world applications, giving participants the tools to identify safety issues, complete state forms, and improve system performance.

Training Details:

• Date: December 17, 2025

• Location: Cochrane Tech Center, Madison Heights, MI

• Instructor: Phil Forner, MIACCA

• Time: 9:00 AM – 3:00 PM EST

• Includes: Course materials, ASME CSD-1 book, Michigan Boiler Rules, and Article 9 of the Skilled Trades Regulation Act

Whether you’re seeking certification for compliance or looking to expand your technical expertise, this class provides a comprehensive understanding of combustion safety and testing procedures.

Register here: CSD-1 Certification Training ›

Explore the Burner Book

For system designers, technicians, and engineers, the Burner Book is a comprehensive reference tool covering everything from flame safeguard logic to pressure control, flow regulation, and burner optimization. It provides technical data, wiring guidance, and product selection support to simplify system design and maintenance.

Download a digital version here.